How Your Picture Frame is *Actually* Made

made in america

Ever wondered about the incredible journey your picture frame undergoes before it graces your walls? Here at Art City Frame Co, we take things seriously when it comes to picture framing. They are not your average picture frame, sanded and stapled together from some garage. We’re talkin’ handcrafted, handmade the right way. Here we will tell you the meticulous process that transforms a simple hardwood lumber board into a work of art, highlighting the craftsmanship, precision, and dedication that goes into every step.

It All Begins with Sustainable Wood Selections

Our first priority is the impact we make in our community with the materials we use. Sourced from sustainable forests, as the trees are harvested more are planted in their place and the process starts over. The wood we use consists of Poplar wood and Knotty Alder, as they are quick to regrow and each handpicked for its quality, straightness, and natural beauty. As each log is cut down by the mill, these boards are sorted even further according to quality then stacked and kiln dried over a long period to ensure a low moisture content which will guarantee stability and longevity of the final product. The lumber is then measured and stacked and shipped to our facility.

Precision with the Gang Rip Saw

Upon arriving at our shop, each piece is then hand placed into our ripper machine, or better known as Gang Rip Saw, where 3-7 blades cut each plank into narrower sticks that are sized for the moulding we will be producing. This process ensures uniformity in width, setting the stage for the next steps in the crafting journey. The sawdust from the rip saw are gathered by our state of the art dust collection system, to be used later. From there we hand select which of those sticks are then custom cut into one of out many house made profile shapes with a machine called a moulder.

Moulding Magic

Enter the moulder, a machine that transforms those strips of wood into the intricate profiles and shapes that define the character of your frame. This machine accomplishes in 1 step what used to take many passes through small routers and shapers; this meant a drop in production time and accuracy of the profile. Cut with what are called knives which are custom ground in house , the sticks exit the machine the perfect completed moulding shape. The Moulder crafts each piece with power and precision, 5 large cutting heads plane and shape all 4 sides of the stick of moulding in one pass with absolute accuracy.

Chopping it Right

The newly molded pieces are then precision-cut to the desired length by our double miter saws. Also state of the art with touch screen measuring systems, these saws ensure seamless joints and sizes when assembled. This step marks the transition from raw materials to the recognizable components of your frame.

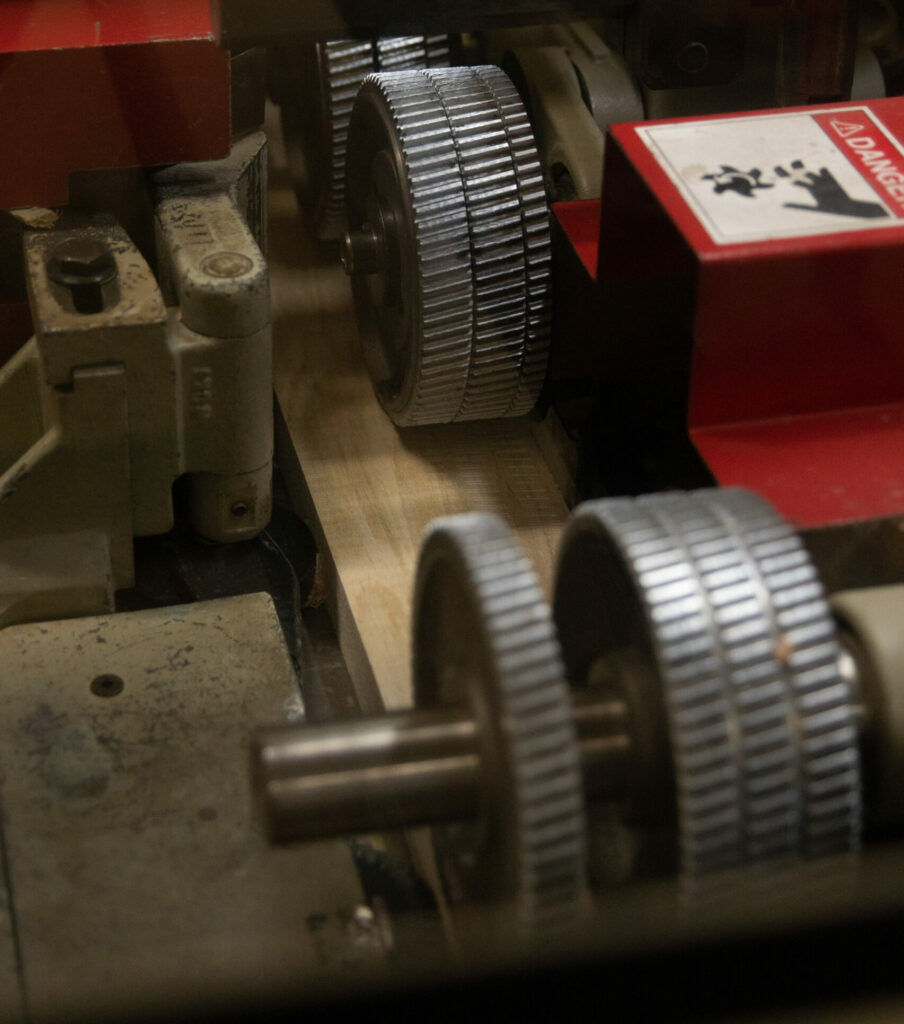

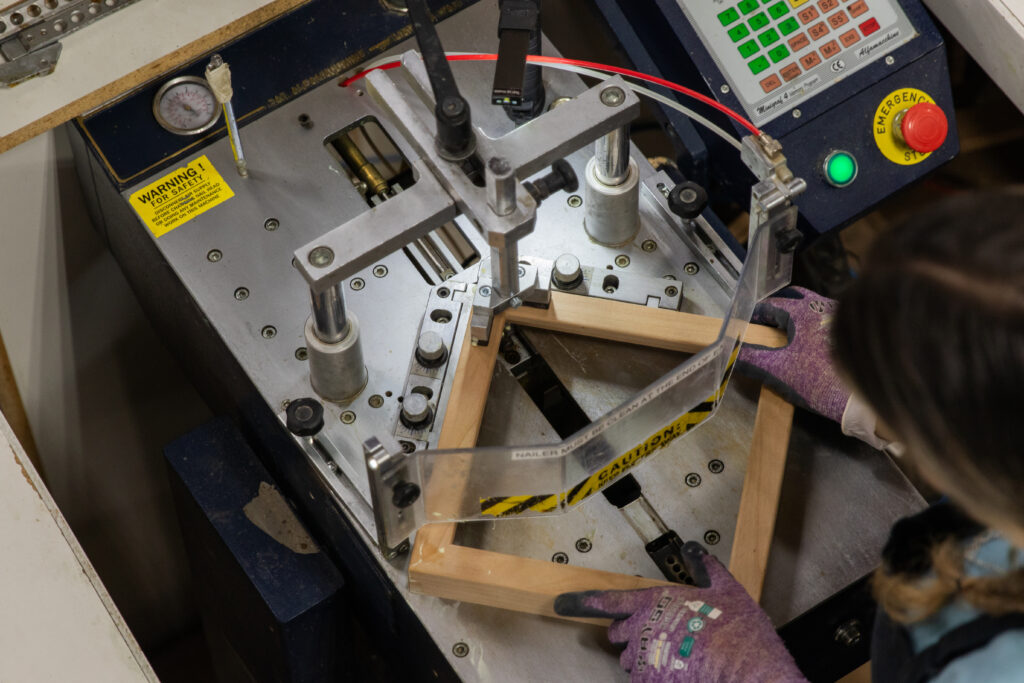

V-Nailer Assembly

The assembly process begins with careful inspection, gluing, and joining the mitered corners of the frame components, creating a sturdy foundation. The frame pieces are first brought over to the joining station. Using a machine called a V-nailer or underpinner, the mitered sides are joined together by inserting V shaped nails into the underside of the frame. This technique uses specialized nails to reinforce the joints, add strength, durability and perfect leveled balance to each corner. It also produces a corner joint with a hidden fastener which is only visible from the back. Gluing and V-nailing the corners together provides a superior miter joint, both in strength and visual appeal, other frame companies just staple or brad nail them together from the side of the moulding which produce weak corners and visual nail holes that look less attractive and easily loosen overtime.

Sanding Smooth

Attention to detail is paramount, and sanding comes next. Skilled craftsmen and women delicately sand each frame, creating a smooth surface that not only feels exquisite but also enhances the natural beauty of the wood. If there are any imperfections or gaps, they are filled in with wood filler and then sanded out to perfection. It is important that we assemble and fill before we sand each frame, which we will cover more in depth in a later post.

Painting and Staining

Now comes the moment of transformation. Depending on the design and customer preferences, frames may be painted with precision or adorned with rich stains, bringing out the unique grain patterns and character of the wood. Our painter brings in rows of assembled frames into the designated painting booth, and gets to work spraying each with sealer, paint, and stain. From there they are laid to dry for a time before assembly. There’s nothing like witnessing the moment a stain is sprayed onto the wood, creating immediate depth and beauty.

Assembling the Puzzle

Once the frames are properly dry, the painted or stained frames are meticulously assembled. From custom orders to wholesale items, every joint and detail scrutinized for perfection. Each opening is measured for mat boards, glass and your artwork to seamlessly fit inside. There is much to cover on this topic alone, which we will save for another post as well.

Quality Check

Quality is non-negotiable. Each frame undergoes a thorough quality check in each step of the way, especially in our final steps. Even when properly assembled with the glass in place, our team looks meticulously for any dust or spots that may have been trapped in the process, to which they will disassemble to retrieve those before sending it out to you. Ensuring it meets the highest standards of craftsmanship, the completed pieces are ready for shipping or pickup.

Ready for Shipping

In conclusion, you frame now a true masterpiece, is carefully packed and prepared for its journey to your doorstep or pickup. Every effort is made to ensure it arrives in pristine condition, ready to adorn your cherished artwork.

The journey from a humble wood plank to a beautifully crafted picture frame is a testament to the dedication, skill, and artistry involved in the framing process. Each step, from the ripper to the hand sanding station, contributes to the creation of a timeless piece that not only enhances your artwork but also tells a story of craftsmanship and attention to detail. Welcome to the behind-the-scenes magic of crafting the perfect frame for your cherished memories.

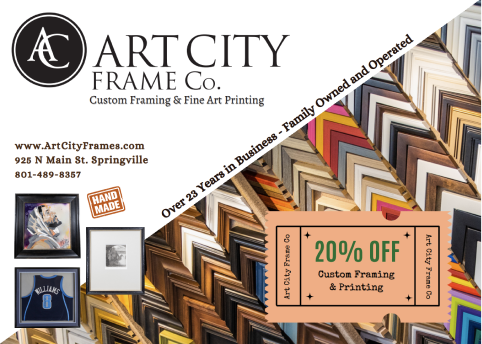

ABOUT US

We are a family owned and operated picture frame shop. My wife and I have been building frames together for ten+ happy years. We specialize in extra wide mouldings and have several different styles and colors to choose from.

LATEST SALE

Find out about our latest sale by entering your email below: